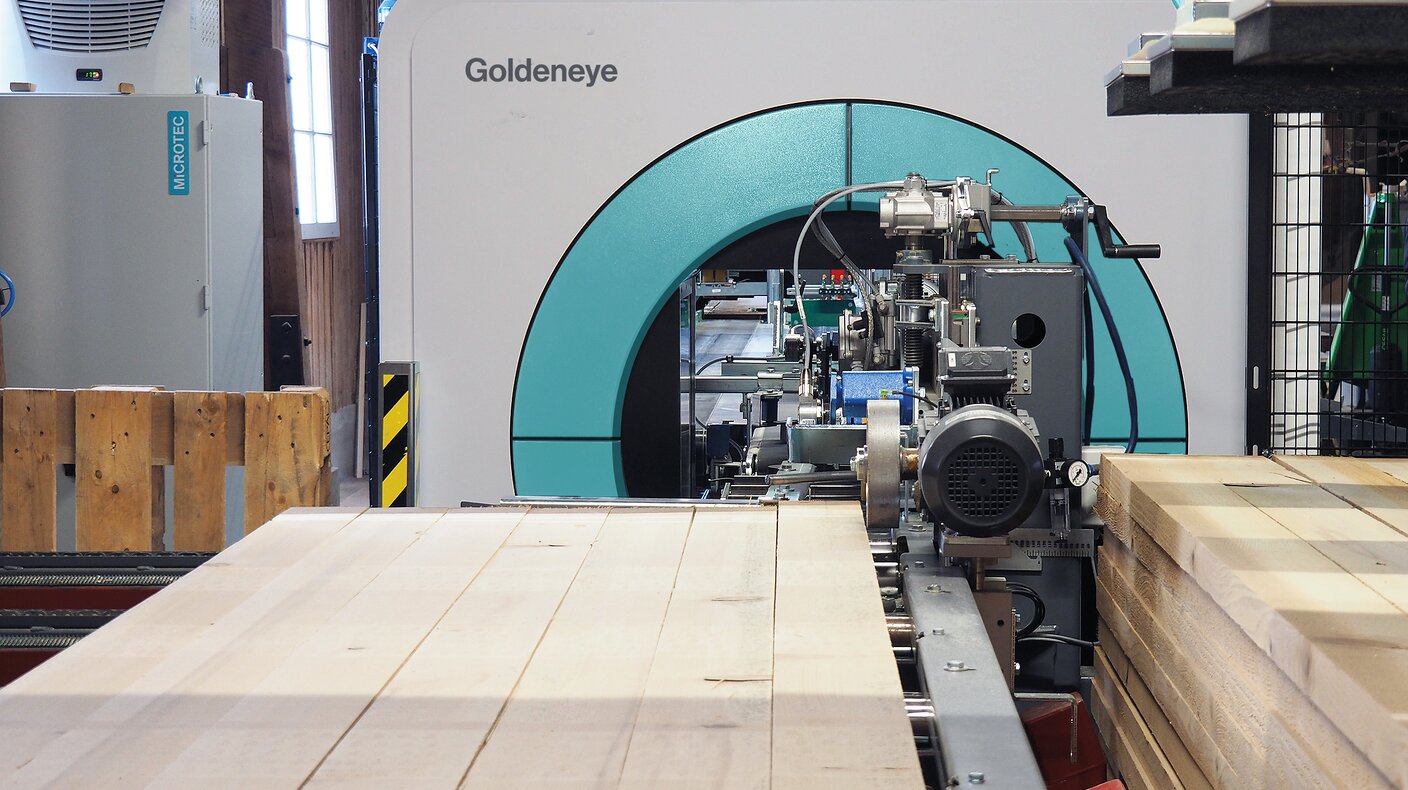

Goldeneye: Better yield and higher efficiency

Olwo Stalden started using a Microtec scanner in its cross-cutting line last year.

Thanks to the precise detection of wood characteristics, Olwo was able to significantly increase yield in terms of quality, while nearly doubling production compared to the past.

Mirco Häfliger, operations manager at Olwo Stalden, lists several reasons for investing in the new scanner cross-cutting line: “The previous machine had become too slow. We believe that silver fir has great potential, especially in the façade segment. That’s why we wanted to increase our production capacity in this area. In addition, we have to invest in automation due to the shortage of employees and skilled workers.” Olwo decided to use a scanner for the detection of wood properties and eventually opted for a Goldeneye scanner by Microtec. “Throughout the industry, Microtec stands for reliable and innovative scanning and measuring systems. We looked at some great references. Also, Microtec was the only supplier who was able to prove that their machines are suitable for scanning rough-sawn silver fir, which was a central requirement,” Häfliger comments.

Fully equipped

Microtec delivered a fully equipped four-sided scanner to Olwo. The scanner is equipped with Microtec’s own Crometic cameras in Full HD resolution, which are divided into multi-sensor and color cameras. Point lasers determine the orientation of the fibers around the branches and the direction of the fibers. “The color camera also detects the tree rings and structure of rough-sawn wood. Detecting both properties in fir wood is particularly important for Olwo, since wavy and straight fibers have to be distinguished,” Peter Hagnberger, CEO of Microtec Rosenheim, explains.

Substantial increase in yield

The employee can see all wood characteristics as well as the scan results on screen, which makes it possible to draw conclusions about yield. “Since we started using the new scanner cross-cutting line, our daily production output has nearly doubled, and yield has also improved both in terms of quality and quantity,” Häfliger tells us and adds: “The scanner’s performance is constant at any time of the day, regardless of whether it’s Monday at seven in the morning or Friday at noon, and the Pinomatic cross-cutting saw then cuts the wood exactly at the point specified by the scanner. A human would add a centimeter or two everywhere just to be on the safe side.” Another advantage of the scanner: “For example, if there is a small knot close to the edge of a piece, which will be planed off in further processing anyway and is therefore irrelevant to the quality of the finished product, the scanner can take this into account,” Hagnberger explains. As mentioned at the beginning, Olwo currently uses this line to process silver fir. Microtec also programmed the scanner to include the classifications for spruce. “Other types of wood can be added at any time,” Hagnberger says.

Extensive training

In order to adjust the scanner to the quality required by Olwo, the Swiss company sent the raw wood to Sweden. Also, Häfliger and some of his employees spent a week in Linköping for training. “Some people might think that this is very time-consuming, but that’s definitely not true. On the one hand, it made the operators more confident in using the technology. On the other hand, we were trained to use our scanner and can adjust settings or change parameters ourselves, if necessary,” the operations manager tells us. Thanks to this training with the respective presettings, Olwo was able to put the Microtec Goldeneye scanner in Konolfingen into operation within a week. “The project handling worked perfectly in every respect,” Häfliger and Hagnberger say praisingly. Olwo Stalden’s operations manager also emphasizes the immediate support in case of questions or problems. Microtec’s technicians can access the Goldeneye scanner at any time via remote maintenance.

The new line can now be operated by just two instead of three employees. Given the doubling of production output, improvement in yield and more homogeneous quality, Häfliger is certain that the scanner cross-cutting line will pay for itself within just a few years.